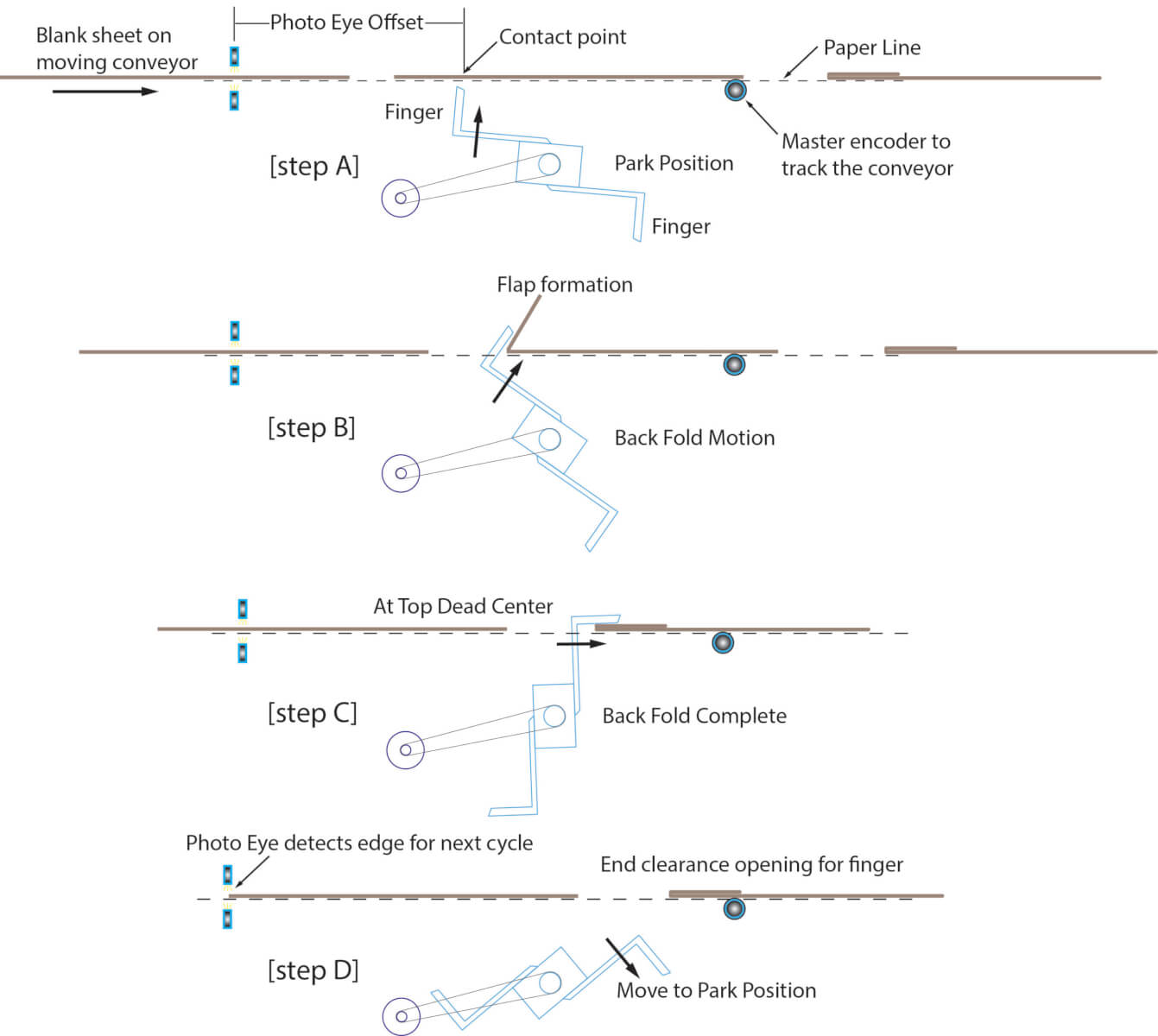

Precision Indexing Motion accurately moves a set of folding fingers that bend a flap to its proper length as the cardboard sheet travels in the forward direction. Folding fingers rotate at the appropriate rate of speed to assure the flap is accurately formed in the shortest time possible and quickly moved out of the way to repeat the process for the next cardboard sheet.

Steps in the back-fold cycle:

Back-Fold Cycle Illustration:

Built-in flexibility using a variety of setup configuration screens allows the operator to adapt the system for different product sizes and folding variations. In-bound and out-bound points of contact are selected based on the desired flap length. Either the in-board or the out-bound servomotor can be enabled or disabled at the operator station. To recall optimum folding cycle rates in the future, the finger size and the number of fingers used for folding become part of a recipe.

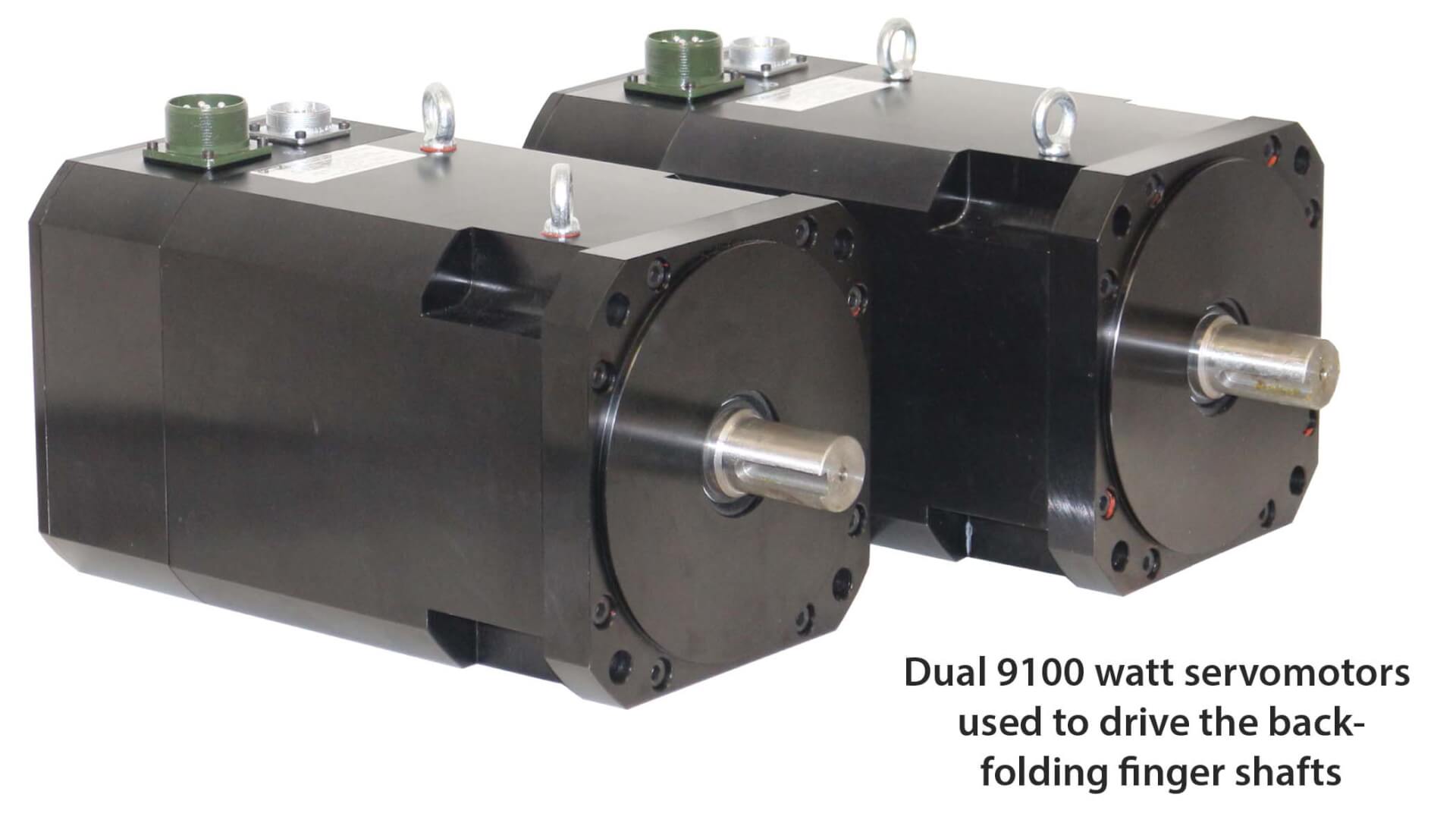

Optimum performance through state-of-the-art automation products provides the speed and agility to achieve aggressive quality production goals. The Emerald Programmable Automation Controller coordinates two brushless servo motors to rotate the back-folding fingers, a master encoder to lock onto the position of the material, and two high-speed photo edge detectors to start the folding cycle.

Modernizing your systems with upgraded automation components from Industrial Indexing Systems provides a system designed to endure in the industrial environment. For added longevity, an airconditioned control cabinet will minimize failure due to overheating the electronic components.

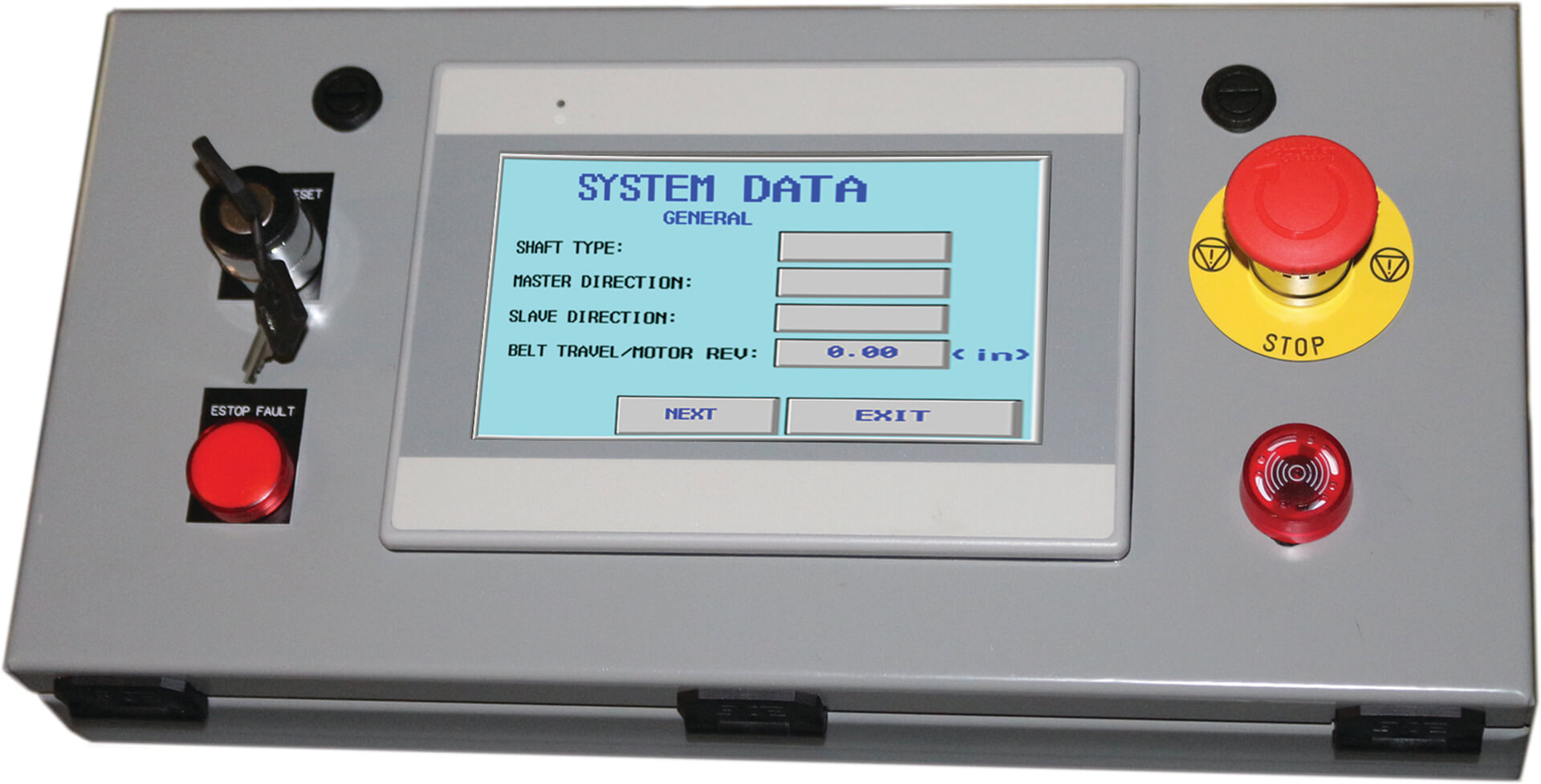

Easy setup sequences, presented by the touchscreen HMI operator interface and stored as recipes, provide quick changeovers and adjustments for fine-tuning the back-folding process. Machine status and diagnostic screens on the HMI can alert the operator minimizing loss of production.

Easy setup sequences, presented by the touchscreen HMI operator interface and stored as recipes, provide quick changeovers and adjustments for fine-tuning the back-folding process. Machine status and diagnostic screens on the HMI can alert the operator minimizing loss of production.

Brushless servo motors ranging from 50w to25kW are configured for factory environments. For food production, medical applications, oil refining, explosive liquid, dust and vapor atmospheres, and submersible environments, we can provide the proper configuration for these complex or harsh requirements based on agency standards UL, cUL, ATEX, IECEx and FDA (rated and certified).