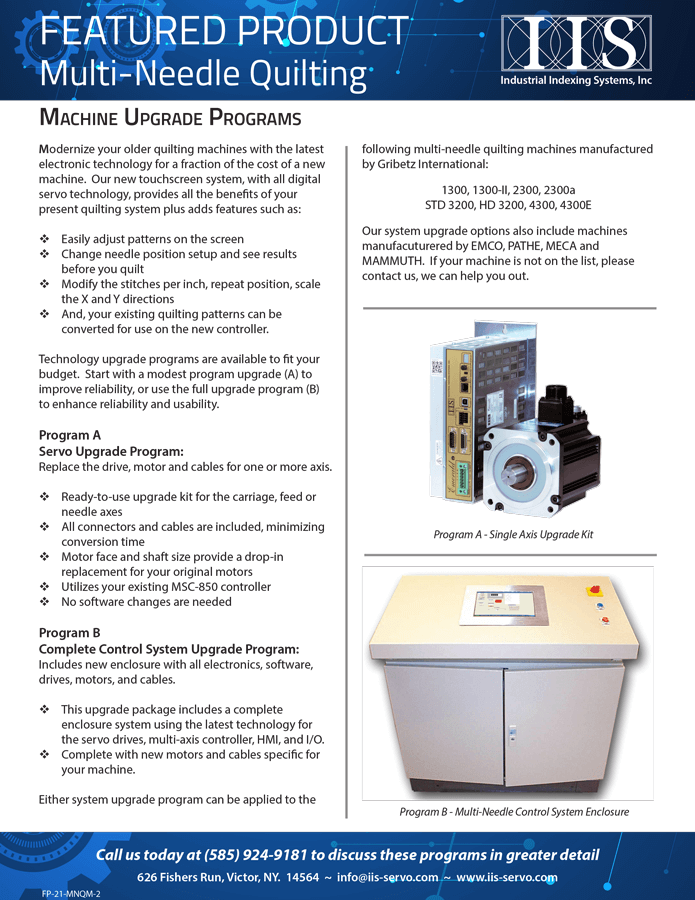

As machinery ages, maintenance and repair becomes costly and, at times, impossible if spare parts are unavailable. When this happens, we have the knowledge of existing applications and offer support in upgrading and retrofitting outdated motion controllers, servo drives, and motors with current technology.

FACTORY MOTION CONTROL SYSTEM AUTOMATION UPGRADE & RETROFIT CAPABILITIES

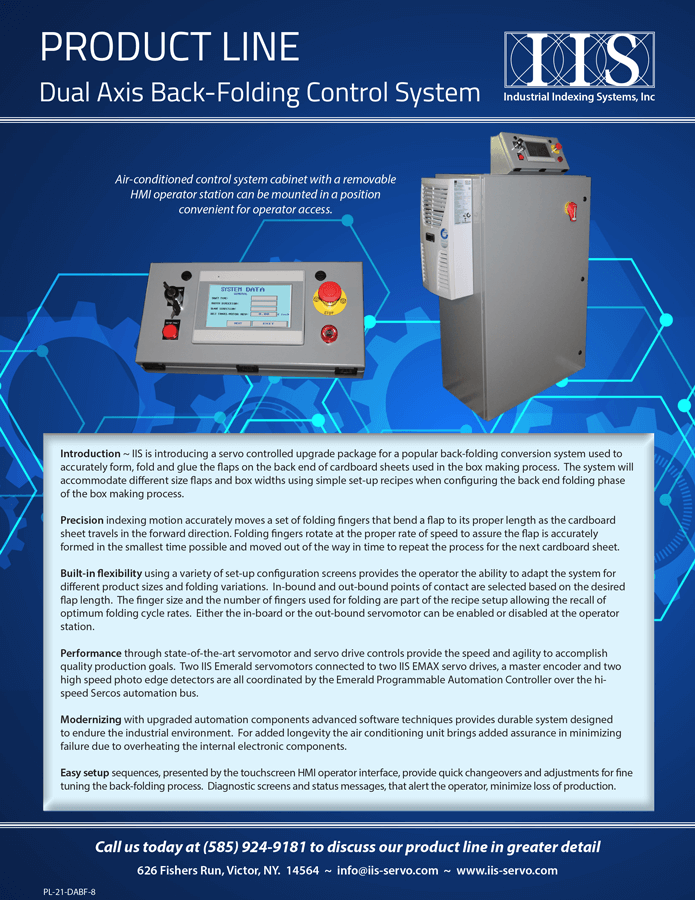

Our factory automation upgrade and retrofit services begin with an upgrade strategy, which includes research and designing pre-engineered packages. Older systems and equipment developed by Industrial Indexing Systems can be upgraded to the newest technology available and all software is completely transferable. We offer upgrade packages for hydraulic or servo driven blow molding, thermoforming, paper and film converting, and multi-needle quilting machines.

Upgrading and retrofitting to modern technology is a proactive plan to minimize downtime and decrease production losses. Upgrades increase system performance and will prolong the life of capital equipment. For more information on our factory automation upgrade and retrofit services, please see below or contact us directly.

Capability Details

- Proactive Upgrade Strategy for Industrial Indexing Systems Equipment

- Knowledge of Existing Application from a Software and Hardware Standpoint

- Research and Design Pre-Engineered Packages

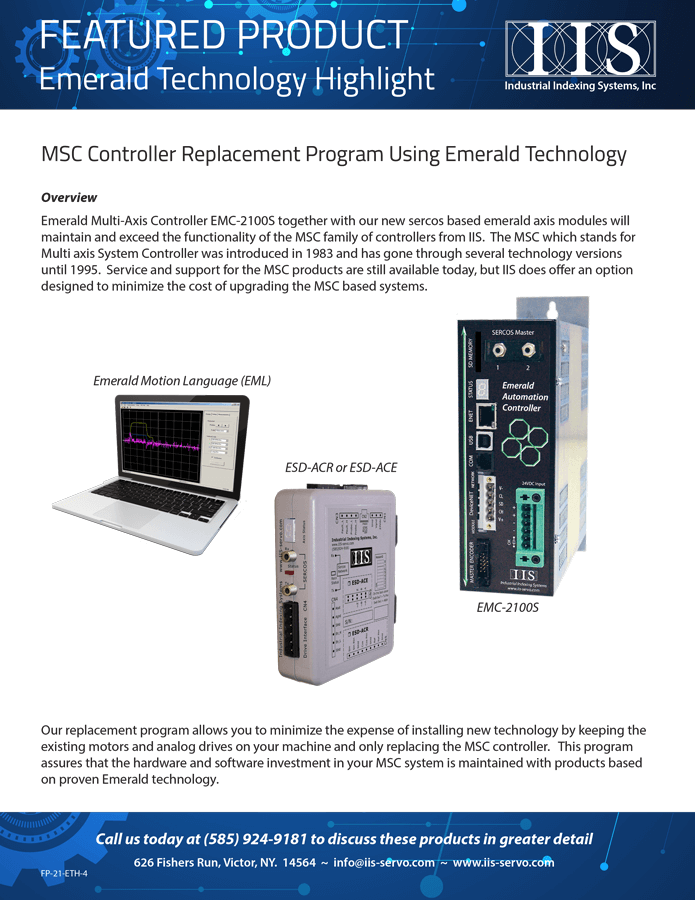

- Support (Any Motion Controller / Amplifier / Motor Developed by Industrial Indexing Systems in use Today can be Upgraded with an Emerald System)

- Transferability (All Software is Completely Transferable to the New Emerald Product Family)

- Upgrade Strategy for non Industrial Indexing Systems Obsolete Equipment

Why Upgrade?

- Greater System Performance

- Greater Reliability and Cost Effective

- Current Technology and New Features

- Prolong Life of Capital Equipment

- Proactive Plan to Minimize Downtime and Decrease Production Losses

- Eliminate Obsolete Equipment and Replace with Readily Available in Stock Equipment

Existing Packages

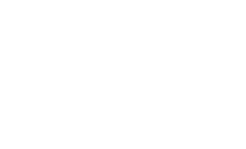

Paper and Film Converting

Folding, Rolling, Drawing, Cutting, Sealing, Punching, Forming Axis plus Controls

Learn More

——————————————————————————————————————————————————————————

Hardware

- Controllers

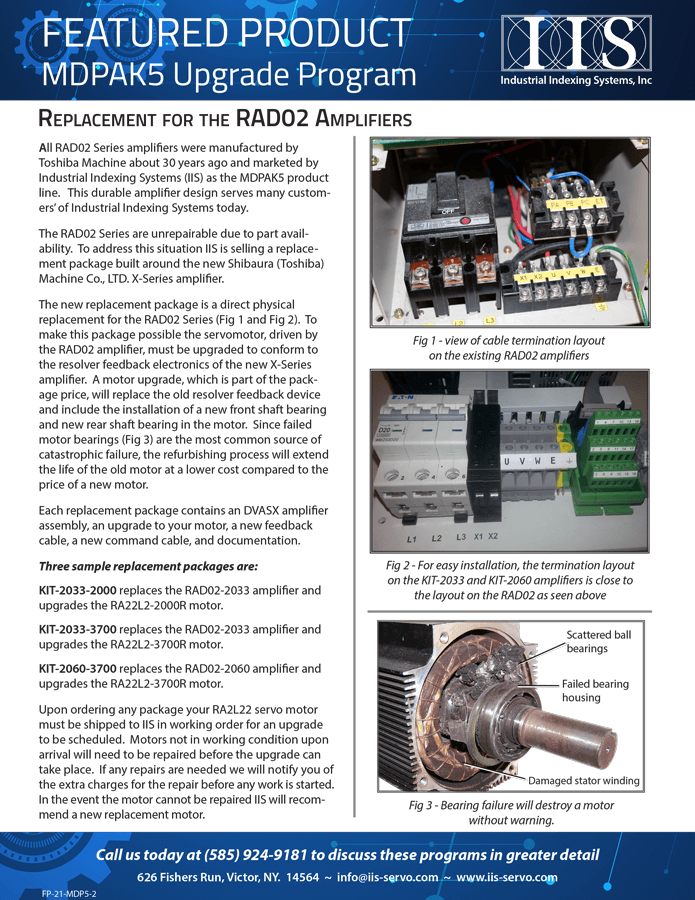

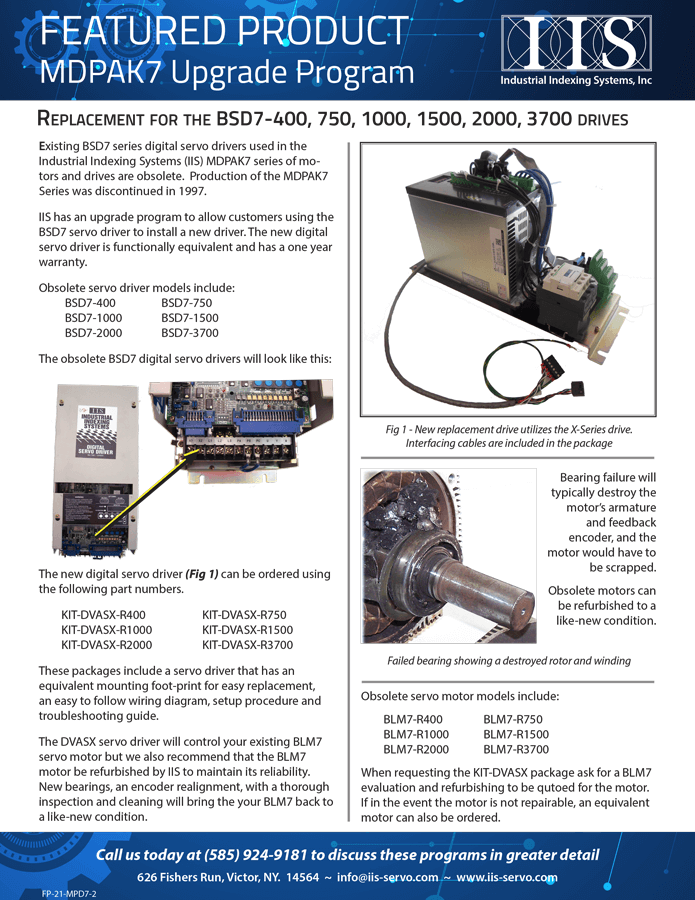

- Amplifiers

- Motors

- Operator Interfaces

- Encoders / Resolvers

- Fiber Optic Components

Software and Firmware

- Motion Application Programs

- Amplifier Parameter Set-Up Software

- Product Firmware

- Operator Interface Screen Development