The EMC-2100 PAC will control up to 32 ESD servo drives and 512 input and output points over a secure optical fiber network. Additional features and capabilities of the ESD family of drives are detailed below.

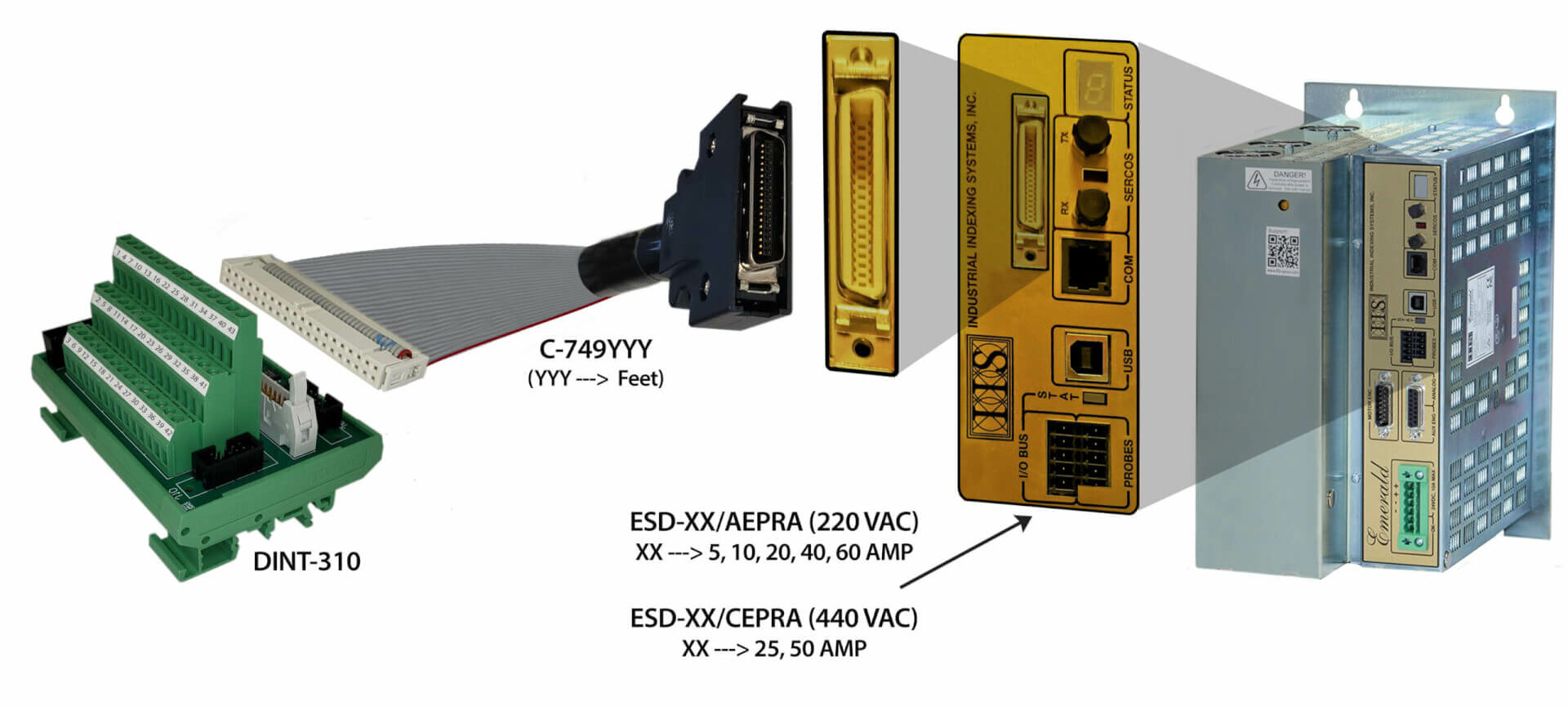

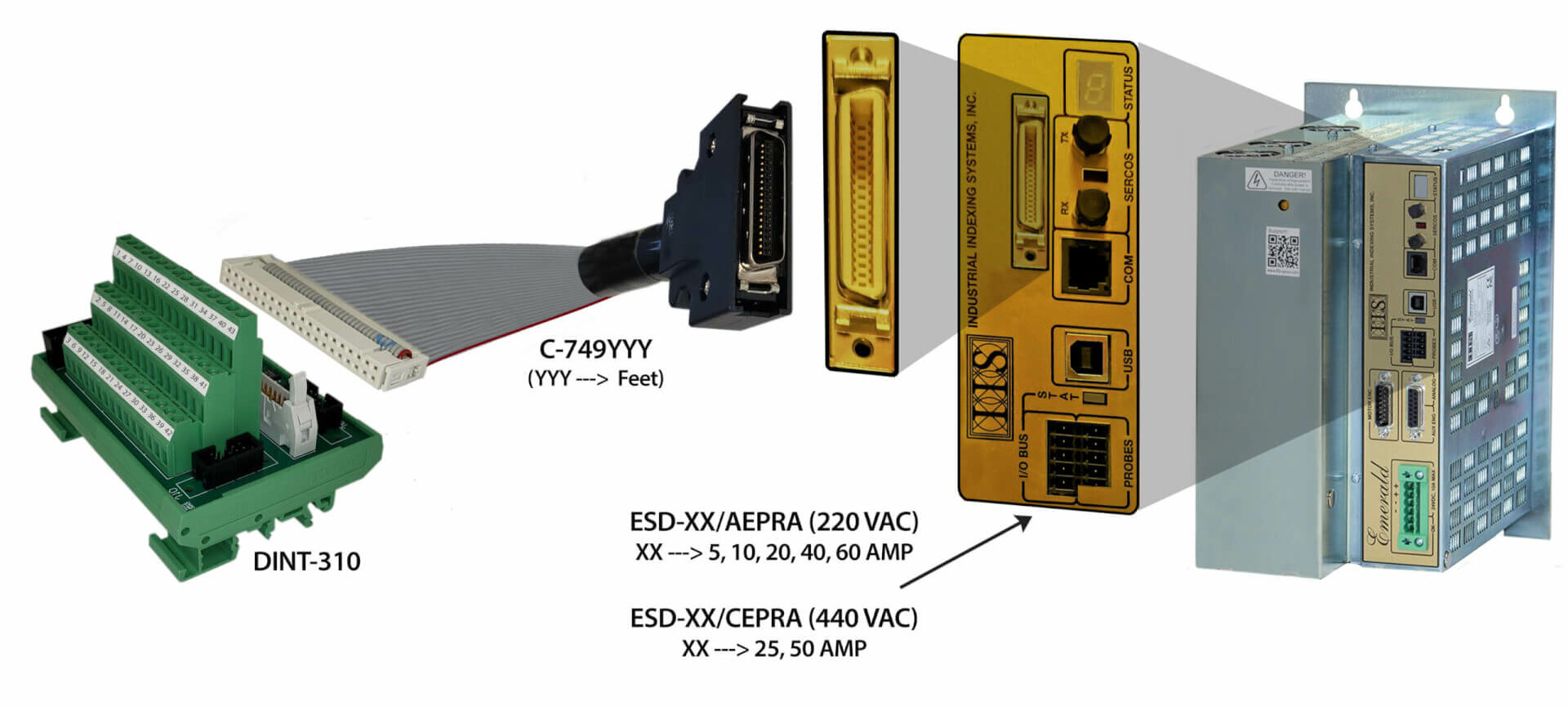

| Model | Continuous Current | Input Power |

| ESD-5/AEP | 5 Amps | 220 Vac |

| ESD-10/AEP | 10 Amps | 220 Vac |

| ESD-20/AEP | 20 Amps | 220 Vac |

| ESD-40/AEP | 40 Amps | 220 Vac |

| ESD-60/AEP | 60 Amps | 220 Vac |

| ESD-25/CEP | 25 Amps | 440 Vac |

| ESD-50/CEP | 50 Amps | 440 Vac |

-

Part # ESD-xx/AEM or ESD-xx/CEM

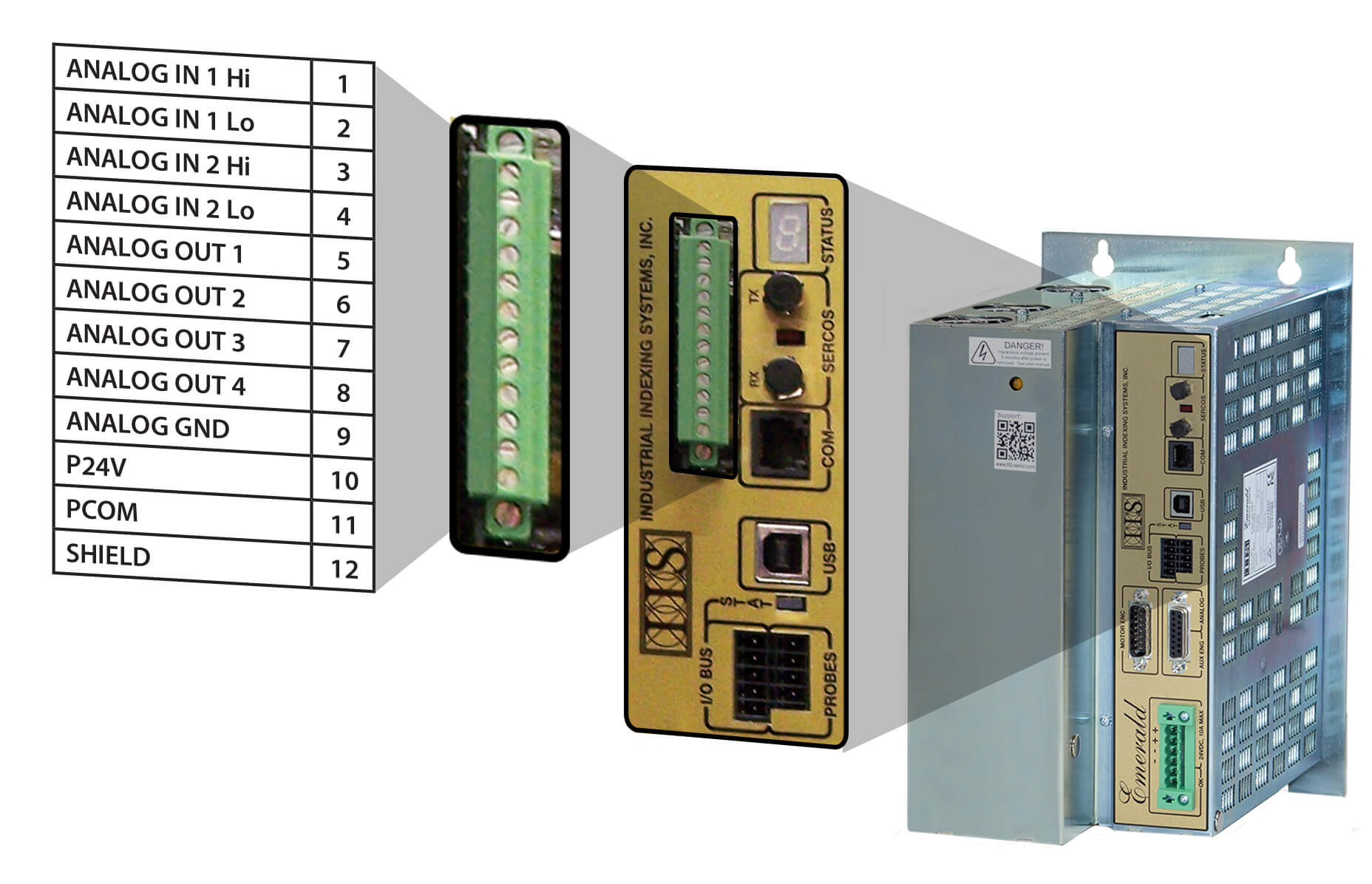

The optional Analog I/O feature provides the Emerald Drive isolated analog inputs and outputs. Powered by 24Vdc, this card feature adds four analog outputs and two differential analog inputs with a ±10Vdc range. The inputs and outputs are accessed through multiple IDNs registers, and each input and output has an adjustable zero offset value. The option includes voltage monitoring to ensure the output voltage is the expected voltage.

-

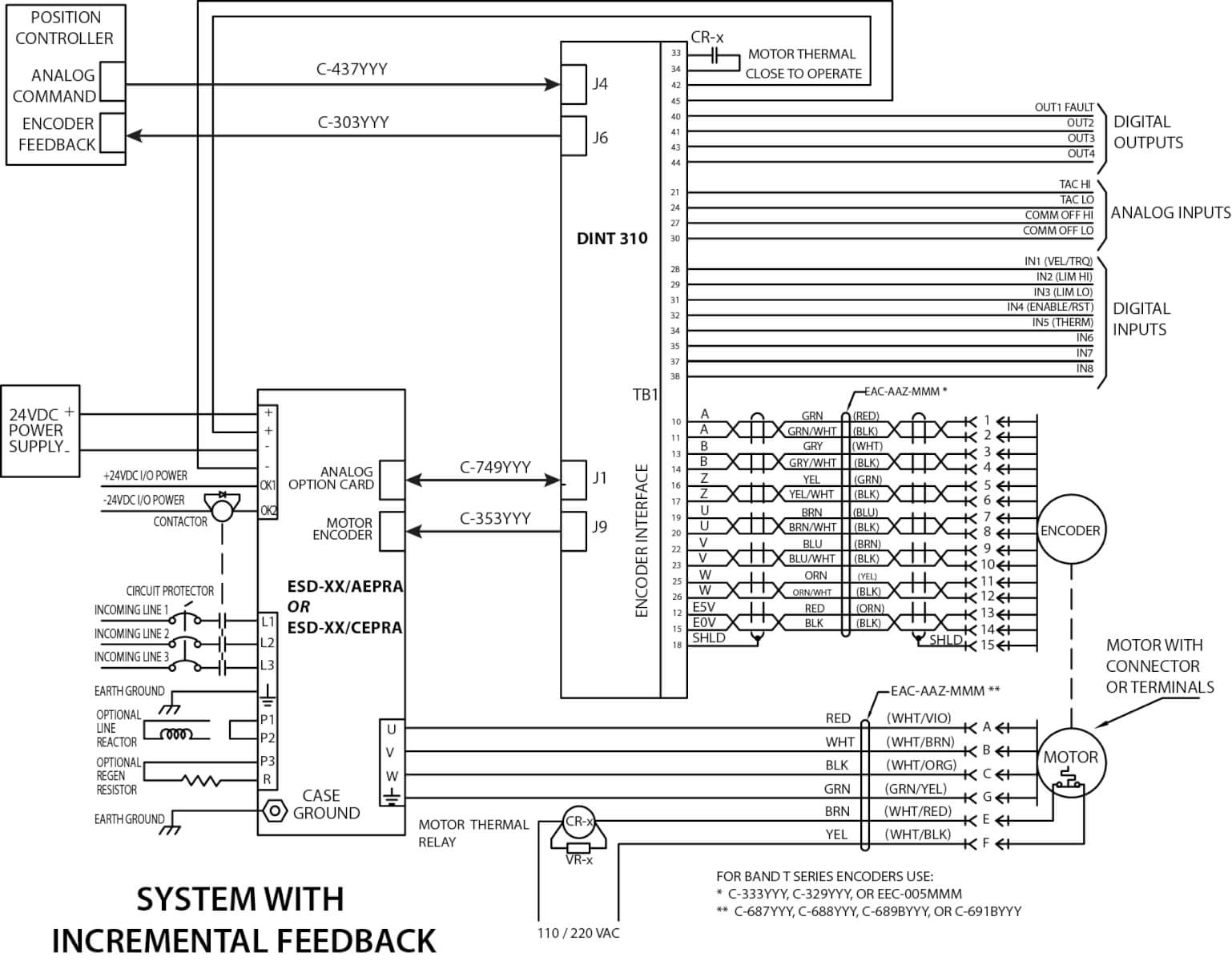

The Analog Control option with encoder feedback allows a digital Emerald Drive to act as an analog controlled servo drive. The encoder feedback device forms a closed loop velocity operation. This configuration can also be part of a legacy servo position loop when used with an analog-based position controller. The eDrive software-based toolkit configures the velocity offset voltage to increase or decrease the velocity command. This feature allows an Emerald drive to be a retrofit drive for an IIS Delta Series drive and as well as other legacy analog-controlled drives.

————————————————————————————————————————————————————————-

-

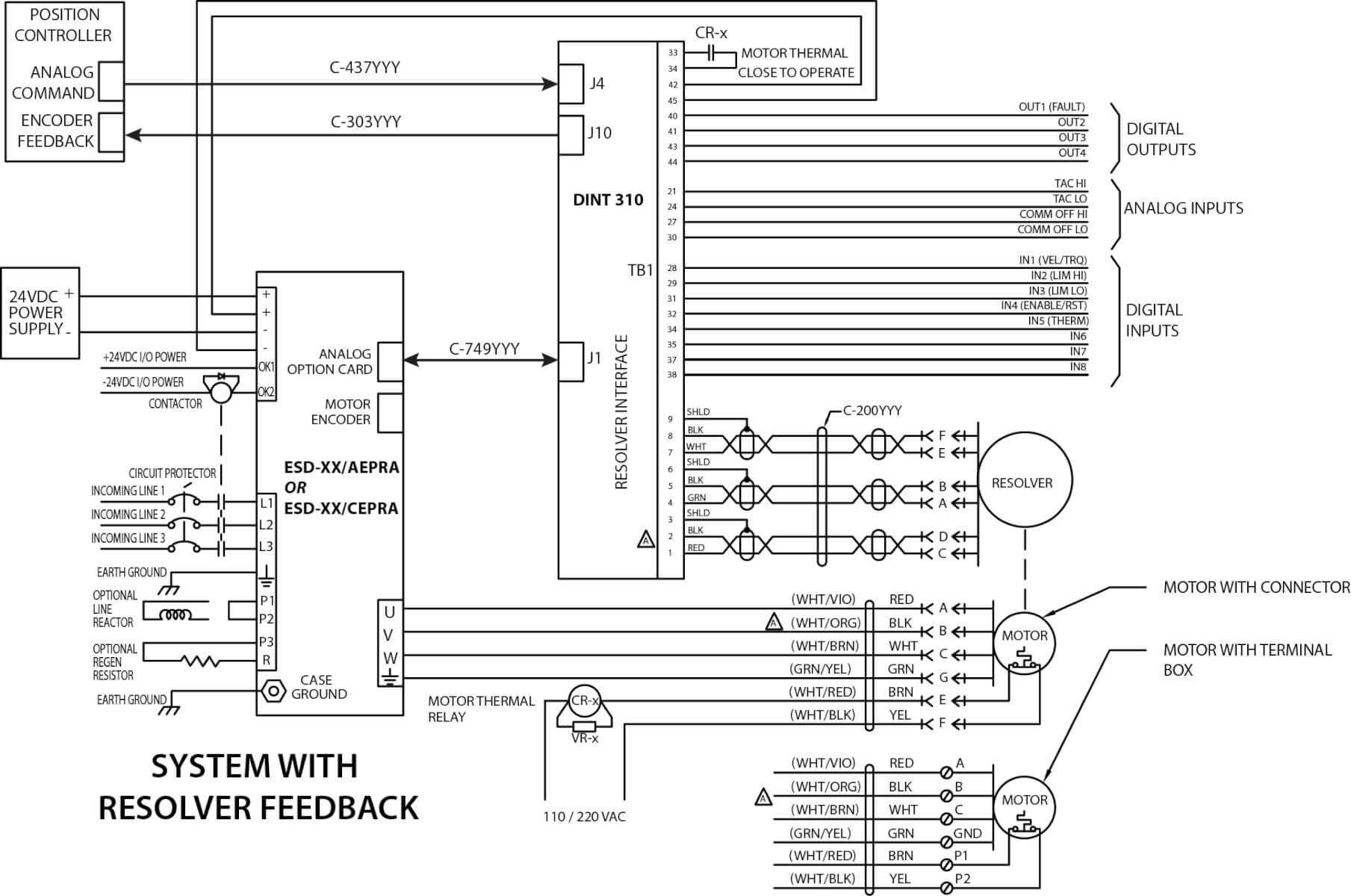

The Analog Control option with resolver feedback allows the digital Emerald Drive to act as an analog controlled servo drive. Feedback devices can be an encoder, resolver, or brushless tachometer-resolver to form a closed loop velocity operation. This configuration can also be part of a legacy servo position loop when used with an analog-based position controller. The eDrive software-based toolkit configures the velocity offset voltage to increase or decrease the velocity command. This feature allows an Emerald drive to be a retrofit drive for an IIS Delta Series drive and as well as other legacy analog-controlled drives.

—————————————————————————————————————————————————————————–

-

-

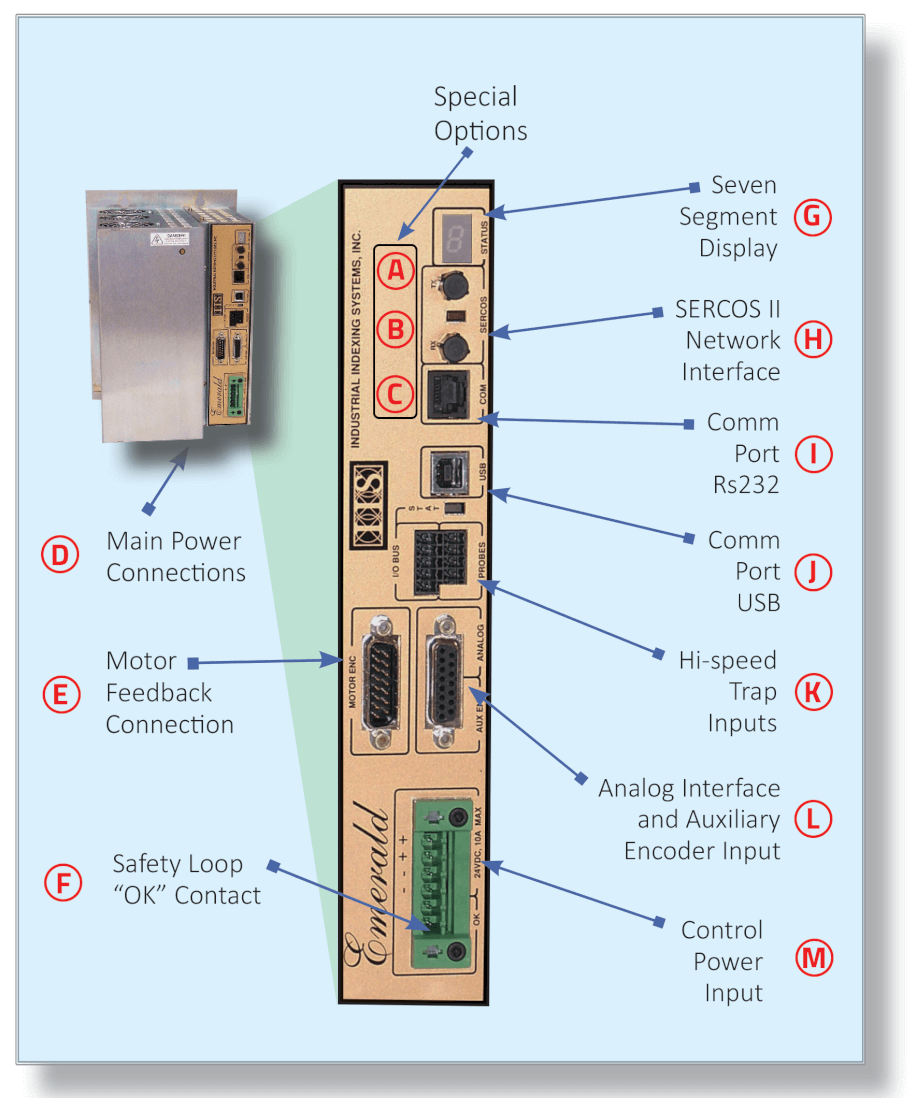

The motor feedback connector will except incremental quadrature ABZ/XYW encoder, and absolute one turn encoder.

-

If the controller stops running, a “watchdog” timer opens the safety-loop contact for system shut-down control.

The “ok” contact would be included as part of your safety circuit.

-

The seven segment status display informs an operator the current state of the drive. Shows the Sercos drive network state, current firmware level, and any fault conditions it may incur.

The seven segment status display informs an operator the current state of the drive. Shows the Sercos drive network state, current firmware level, and any fault conditions it may incur. -

SERCOS red indicator light shows a signal loss in the cable.

SERCOS red indicator light shows a signal loss in the cable.

~ If the indicator light is off, the signal is ok.

~ If it flickers, the signal is getting weak.

~ If it is on steady and bright, the cable is not connected, the cable is faulty, the receiver unit (RX) is defective, or the transmitter (TX) on the opposite end is defective. -

This port is available to monitor and adjust the drive performance using the EDrive software running on a Windows PC.

-

USB port for easy interfacing to a laptop PC for drive diagnostic and setup procedures using a C-USB,A/B cable with the Edrive software program.

-

Two isolated edge-trigger inputs are available to trap or capture an encoder count with minimal delay. The trapped encoder count is used for precise web or product registration operations.

-

Provides access to two functions, an analog I/O feature and an encoder interface.

a) One +/- 10Vdc analog voltage input. One PWM style output. Constant frequency with a 50/50 duty-cycle represents zero voltage output.

b) Connect an incremental encoder for use as a external master/pacer axis

-

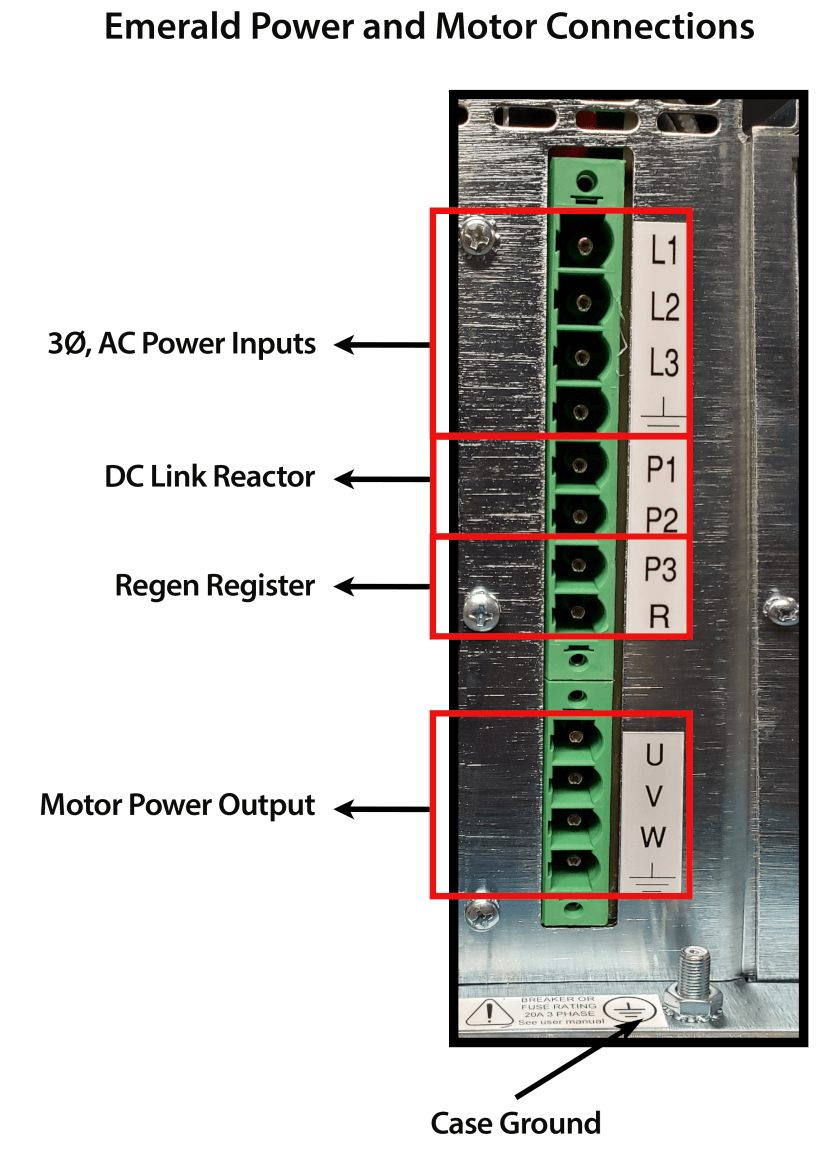

The Emerald drive controller power is connected to a 24 Vdc supply.

The control power connector has multiple power pins to ease the wiring connections. Drive power can be daisy chained to connect back to power supply.

When sizing the 24Vdc supply, the load requirements of each drive must be summed up to determine the current rating of the supply. The maximum current that can be carried by the chain is 10 amp dc.