Understanding Servo Motors

Servo motors are the unsung heroes of modern automation systems. These precision devices are designed to control various applications’ position, velocity, and acceleration accurately. What sets servo motors apart is their ability to offer precise movements, high speeds, and remarkable adaptability to changing production requirements.

In the realm of food and beverage, servo motors shine for several reasons:

- Precision: Servo motors can achieve positioning accuracies down to fractions of a millimeter, ensuring consistent and reliable packaging operations.

- Speed: With the capability to operate at high speeds, servo motors significantly boost production rates without compromising accuracy.

- Adaptability: These motors can quickly adjust to different package sizes, shapes, and materials, making them ideal for versatile production lines.

Industrial Indexing Systems (IIS) offers a range of servo motors that are optimal for the food and beverage industry. Their power outputs range from 30 to 55,000 Watts and speeds from 1500 to 6000 RPM. This wide range ensures a perfect motor for every packaging application, from small-scale operations to large industrial setups.

Applications in Food and Beverage Packaging

Filling Operations

Precise control is paramount when filling containers with liquids or solids. Servo motors enable accurate product dispensing, minimizing waste and ensuring consistent fill levels. Whether bottling beverages or packaging dry goods, servo-driven filling systems can adapt quickly to different container sizes and product viscosities.Capping and Sealing

Proper sealing is crucial for the integrity of food and beverage packaging. Servo motors provide the precise torque control needed to apply caps or seals with the right force. This ensures a secure seal without damaging the packaging or overtightening, which could lead to customer frustration.Labeling

Servo motors shine in labeling applications where branding and information accuracy are crucial. They offer the precision required to apply labels consistently, even at high speeds. This is particularly important for products that require exact label placement for aesthetic or regulatory reasons.

Conveyor Systems

Servo motors excel in controlling conveyor belts, allowing for smooth acceleration, deceleration, and precise positioning of products along the packaging line. This level of control is essential for synchronizing various packaging processes and ensuring efficient product flow.Integration with Automation Systems

The true power of servo motors in food and beverage packaging is realized when they are integrated into comprehensive automation systems. IIS’s advanced servo solutions are designed to integrate with modern control systems, offering seamless:

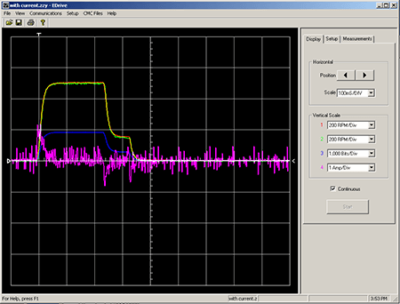

User-friendly programming: IIS provides intuitive software tools like EDE (Emerald Development Environment) for easy system configuration and management.

User-friendly programming: IIS provides intuitive software tools like EDE (Emerald Development Environment) for easy system configuration and management.- Tested application libraries: Pre-configured solutions for common packaging tasks accelerate implementation and reduce development time.

- Enhanced safety protocols: Built-in safety features protect equipment and operators, ensuring compliance with industry standards.

Combining servo motors with sophisticated control systems can enable packaging lines to achieve unprecedented efficiency and flexibility. This integration allows for real-time adjustments, predictive maintenance, and data-driven optimization of packaging processes.

The Future of Packaging Automation

As the food and beverage industry continues to evolve, the role of servo motors in packaging automation is set to expand further. Emerging trends include:

- IoT integration: Servo-driven systems connected to the Internet of Things will enable remote monitoring and control, enhancing operational efficiency.

- AI-powered optimization: Machine learning algorithms will leverage data from servo motors to refine packaging processes continuously.

- Sustainable packaging solutions: The precision of servo motors will be crucial in implementing eco-friendly packaging methods that minimize material waste.

Embracing Servo Technology

Automating food and beverage packaging processes represents a significant leap forward for the industry. Servo motors, unparalleled precision, speed, and adaptability are at the forefront of this transformation. By implementing servo-driven automation solutions, companies can achieve higher production rates, improved quality control, and greater flexibility in their packaging operations.

Automating food and beverage packaging processes represents a significant leap forward for the industry. Servo motors, unparalleled precision, speed, and adaptability are at the forefront of this transformation. By implementing servo-driven automation solutions, companies can achieve higher production rates, improved quality control, and greater flexibility in their packaging operations.

In an industry where efficiency and quality are paramount, embracing servo motor technology is no longer a luxury—it’s a necessity for staying competitive. As we look to the future, the role of servo motors in food and beverage packaging will only grow, paving the way for smarter, faster, and more sustainable production processes.