The coil, spring, and metal manufacturing industry, a highly competitive sector, is currently experiencing a seismic shift due to advancements in automation. Despite such progress, there exist numerous automation issues that, once resolved, can vastly improve productivity, efficiency, and operational performance.

The coil, spring, and metal manufacturing industry, a highly competitive sector, is currently experiencing a seismic shift due to advancements in automation. Despite such progress, there exist numerous automation issues that, once resolved, can vastly improve productivity, efficiency, and operational performance.

Enhancing Precision and Accuracy

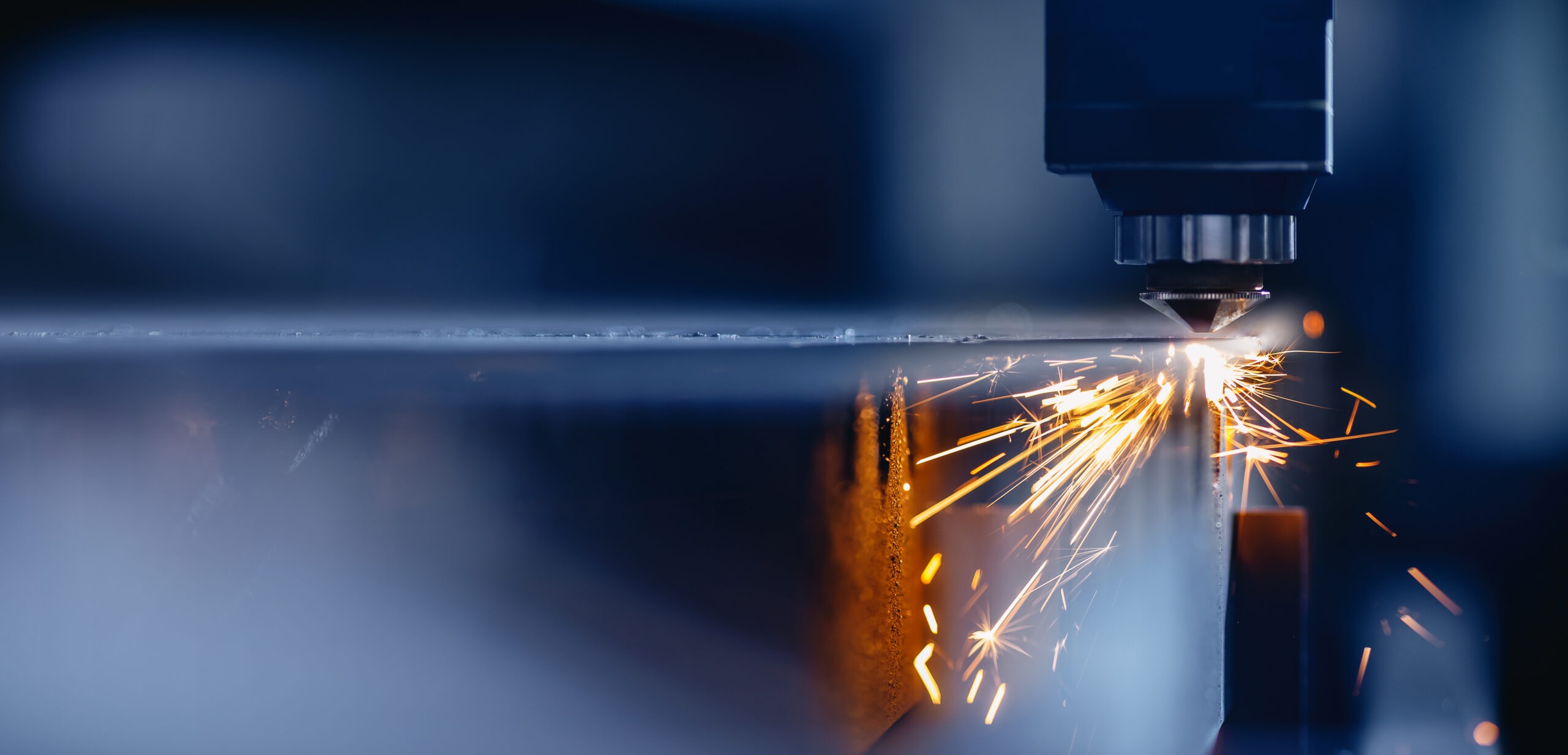

Precision and accuracy are paramount in this industry. Advanced robotics, CNC machines, and computerized control systems are reshaping manufacturing processes. They offer precise control over cutting, bending, coiling, forming, punching, and many secondary operations. This precision results in consistent quality, reduced errors, and a satisfied customer base.

Increasing Speed and Throughput

With fierce competition, the pressure to increase production speed and throughput is substantial. High-speed coil winding machines, robotic assembly systems, and automated material handling systems address this issue. These solutions, based on servo motion control, optimize workflow, decrease downtime, and streamline production processes, increasing throughput and maintaining high quality.

Optimizing Material and Reducing Waste

Optimizing Material and Reducing Waste

Effective material management is critical for cost-efficiency. Automation solutions incorporating intelligent nesting algorithms, material tracking systems, and automated material feeding optimize material utilization. These systems precisely position materials, minimize waste, and enhance cost-effectiveness – providing a substantial boost to your ‘green’ PR initiatives.

Improving Tooling and Setup Efficiency

Efficient tooling management and setup processes directly influence production efficiency. Automation systems offer quick and automated tool changes, tool wear monitoring, and setup optimization, reducing downtime and enhancing overall efficiency. The end result is improved tooling utilization, faster changeovers, and minimal production interruptions.

Elevating Quality Control and Inspection

Product quality and defect detection are vital in this industry. Automation solutions incorporating vision inspection systems, real-time monitoring, and automated defect detection algorithms enhance quality control processes. These systems identify and eliminate non-conforming products almost instantly, reducing the risk of scrapped parts and improving customer satisfaction.

Streamlining Workflow and Integration

Seamless workflow and production process integration are key to efficient operations. Automation systems that integrate with upstream and downstream processes like material handling, heat treatment, and post-processing enhance workflow efficiency. Such integration ensures smooth material flow, eliminates bottlenecks, and optimizes overall production efficiency and quality.

Leveraging Data Collection and Analysis

Leveraging Data Collection and Analysis

The collection and analysis of production data are crucial for process optimization, quality control, and continuous improvement. Automation systems capable of capturing and analyzing real-time data on key parameters facilitate proactive decision-making, predictive maintenance, and continuous improvement initiatives. Predictive maintenance, in particular, can significantly improve productivity and reduce costs.

Prioritizing Worker Safety and Ergonomics

In an industry where manual labor is still prevalent, worker safety and ergonomics are of utmost importance. Automation systems that incorporate safety interlocks, emergency stop buttons, and safety sensors ensure worker safety and prevent accidents. Ergonomic considerations in workstation design help reduce physical strain and risk of workplace injuries, potentially yielding positive impacts on labor relations.

Addressing these factory automation issues in the coil, spring, and metal manufacturing industry requires collaboration between equipment manufacturers, automation experts, and industry professionals. Leveraging advanced automation technologies, such as servo motion control, integrating systems, and optimizing workflows can revolutionize this sector, leading to increased efficiency, productivity, product quality, and worker safety.