As industries across the globe move towards Industry 4.0, businesses are harnessing the power of advanced automation to stay competitive. One key component in this digital transformation journey is the adoption of new automation controllers. These sophisticated devices, at the heart of any automation system, promise a myriad of benefits to businesses, including streamlined processes, enhanced accuracy, and improved safety.

As industries across the globe move towards Industry 4.0, businesses are harnessing the power of advanced automation to stay competitive. One key component in this digital transformation journey is the adoption of new automation controllers. These sophisticated devices, at the heart of any automation system, promise a myriad of benefits to businesses, including streamlined processes, enhanced accuracy, and improved safety.

Streamlined Operations and Enhanced Efficiency

A central motivation for upgrading to new automation controllers is the significant improvement in operational efficiency. These controllers can manage multiple tasks simultaneously, orchestrating complex industrial processes with ease. This parallel processing capability accelerates workflows, reduces processing time, and significantly boosts overall productivity—an invaluable asset in today’s fast-paced, demand-driven marketplaces.

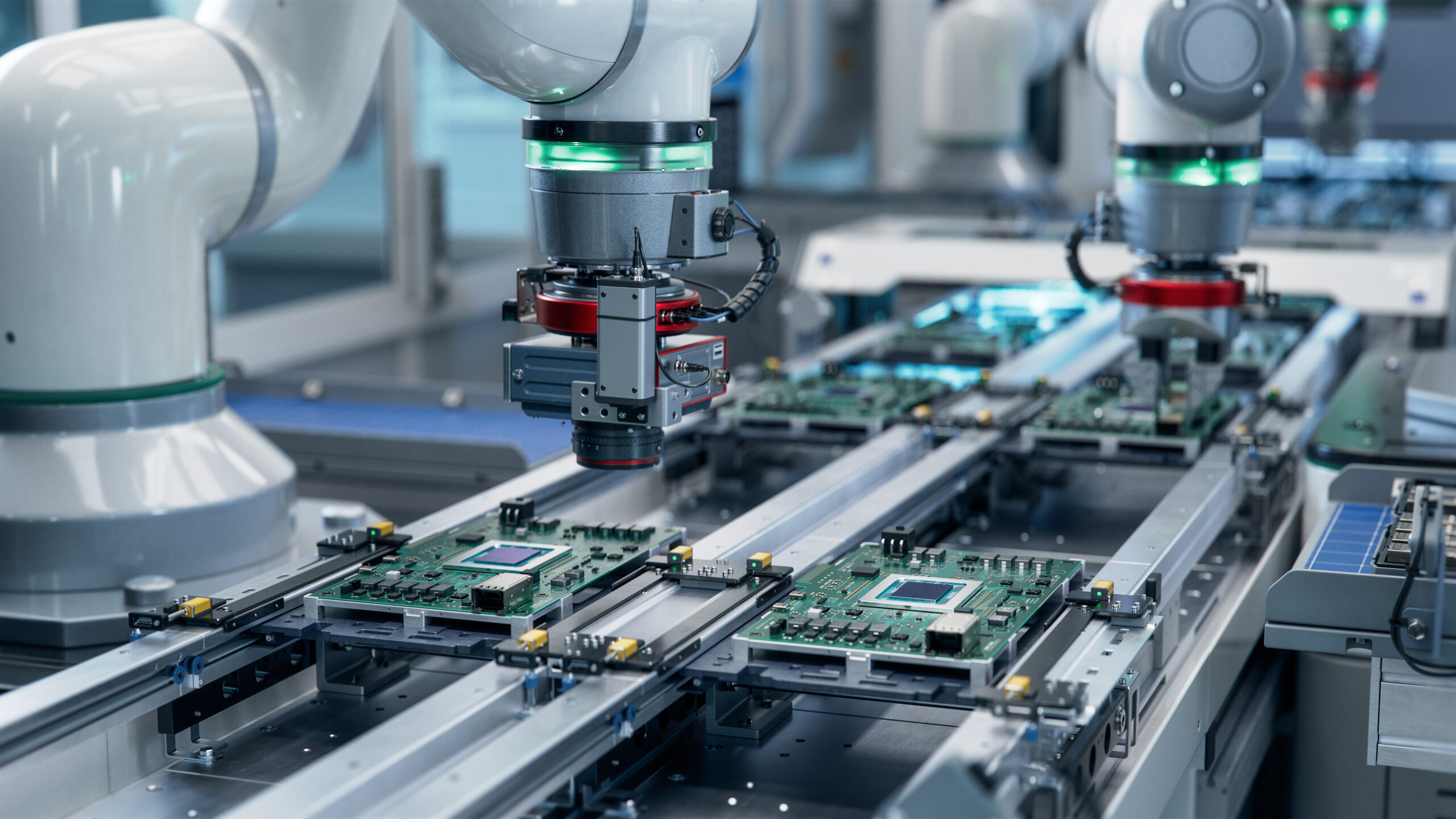

Precision and Repeatability

New automation controllers execute tasks with a high level of precision, enhancing the overall quality of the output. These systems maintain a level of consistency and repeatability that human operators simply can’t match, thereby minimizing production errors. This superior accuracy not only results in high-quality products but also reduces material waste, contributing to cost savings.

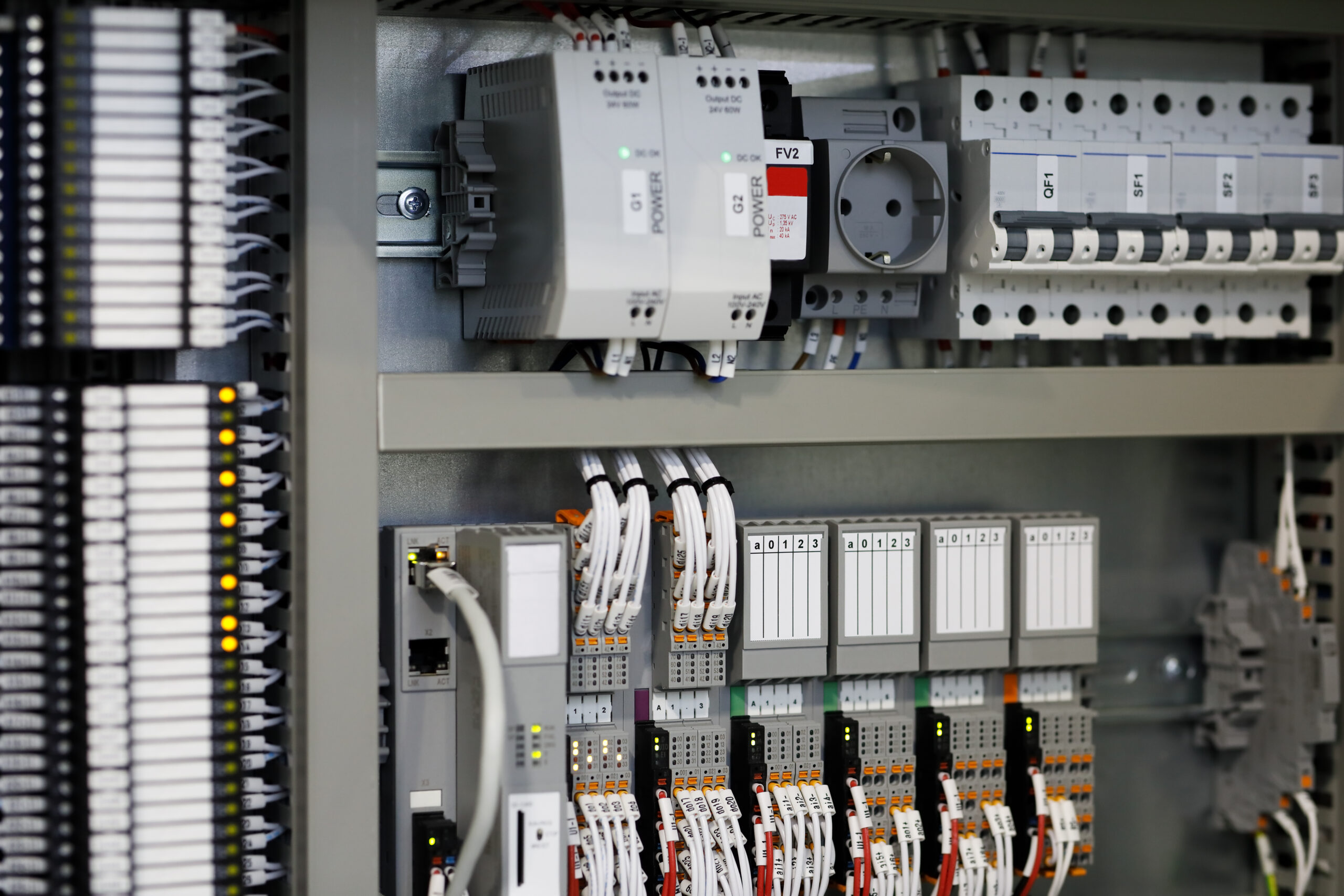

Seamless Integration

The potential for seamless integration with other devices and systems is another persuasive argument for upgrading to modern automation controllers. With the capability to centrally manage and control various aspects of an industrial process or building automation, businesses can achieve higher system interoperability and data sharing, enhancing their ability to make informed decisions.

Scalability and Adaptability

As businesses evolve, their requirements can change significantly. Modern automation controllers are designed with this flexibility in mind. They can be easily expanded or adjusted to accommodate growth or changes in processes and equipment. This scalability future-proofs businesses, providing them with a versatile solution that can adapt alongside their growth and diversification.

Safety Enhancement

By automating potentially hazardous tasks, new automation controllers increase worker safety. They help minimize human intervention in dangerous operations, creating a safer work environment and potentially contributing to improved labor relations.

Remote Monitoring and Control

Remote Monitoring and Control

In the age of remote work, the ability to access, monitor, and control systems from anywhere via the Internet is invaluable. This feature allows for real-time system control and performance optimization, irrespective of location. It provides businesses with the flexibility they need in an ever-changing work environment.

Financial Efficiency

By reducing labor costs and improving resource utilization, automation can significantly impact a company’s bottom line. The reduced incidence of errors leads to less waste, while improved efficiency can result in higher output—all culminating in cost savings.

Proactive Maintenance

Automation controllers play a pivotal role in predictive maintenance. By continuously monitoring equipment health and predicting potential failures, businesses can shift from reactive to proactive maintenance strategies. This reduces downtime, extends equipment life, and leads to substantial long-term savings.

Enhanced Decision-Making

Automation controllers collect and analyze data from various sources, providing businesses with real-time information. This empowers companies to make data-driven decisions, identify bottlenecks, and continually optimize processes.

In conclusion, the decision to upgrade to new automation controllers is a strategic move for businesses in the pursuit of improved productivity, cost-effectiveness, and competitiveness. Businesses need to capitalize on the benefits these advanced systems offer in this era of rapid digital transformation.