A plastic bag and converting machine manufacturing OEM is utilizing high performance servo controls for quick axis indexing, handling large inertial loads and simplifying its HMIs with built-in communication protocols. Century Tech (www.century-techinc.com) manufactures three different types of servo-driven packaging machine using IIS automation controllers, drives and system accessories

Servo Wicketers

The company’s Century Tech line of servo-wicketer bagging machines use servos to control a combination inverse/unwind/center folder on a common frame, implementing electrically controlled web and tension adjustments. Key features include precise tension-controlled web converting, a header/sealer and a double unwind stand for more flexible production.

Side-Weld Bag Machines

A line of side-weld bagging machines convert a plastic web of material using variable frequency drives (VFD) and a touchscreen operator interface. This solid roll, single servo design implements an auxiliary draw roller and proximity sensor for capstan control, and eliminates use of plastic gears that break and hinder fine adjustments of machine operation.

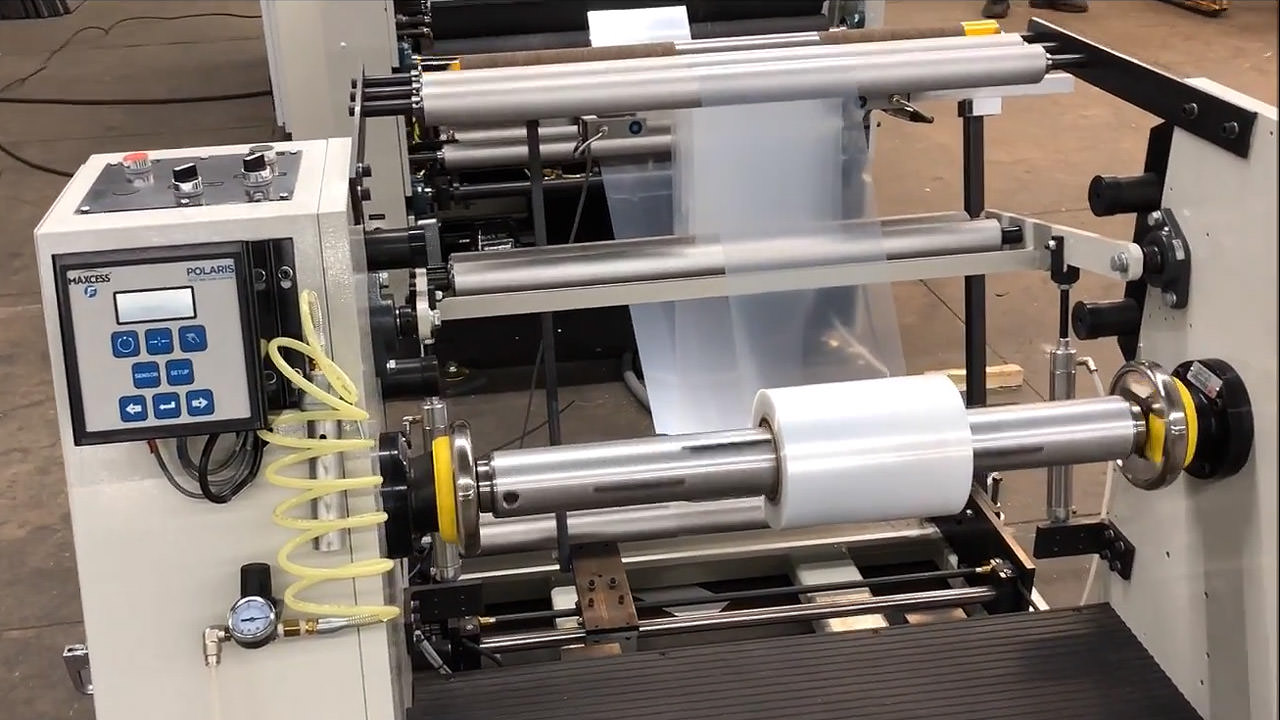

Bottom Seal Machine

The Century-Tech CT-9030 uses a 30” solid roll servo to create a bottom seal machine featuring a servo-controlled flying knife, and options for a tension controlled unwind stand and a registration scanner for precise cutoffs using printed material.