March 2023

Welcome back to our bi-annual news report!

When we strive to become better than we are, everything around us becomes better too.

You will find the latest marketing/sales news, website updates, product information, and more, so bookmark this webpage location for future relevance as it’s not accessible via the IIS website.

Please feel free to share your feedback and suggestions to help us improve via Tina Ebmeyer at tinae@iis-servo.com

Thank you for your time

Website Updates

Click on the drop down boxes and select the material/links to download/view

-

We found ourselves having continuous interest in our Dual Axis Back-Folding Control System. This is currently on our NEWS page with links to Landing Pages on this product. We have updated the landing pages with a video and a GIF illustrating the motion process:

We found ourselves having continuous interest in our Dual Axis Back-Folding Control System. This is currently on our NEWS page with links to Landing Pages on this product. We have updated the landing pages with a video and a GIF illustrating the motion process:Landing Page #1: https://www.iis-servo.com/news/dual-axis-back-folding-control-system/

Landing Page # 2: https://www.iis-servo.com/dual-axis-back-folding-control-system/

GIF Illustration: https://www.iis-servo.com/wp-content/uploads/2023/01/Fingers-Moving-Version-2.mp4

Video: https://www.iis-servo.com/wp-content/uploads/2023/01/Dual-Axis-Back-Folding-Video.mp4

Product Brochure: Product Brochure

The GIF and Video are also available on our Press Kit under the tab categories:

- Animated GIF Adverts

- Videos

- Digital Artwork – Product Photo Images

-

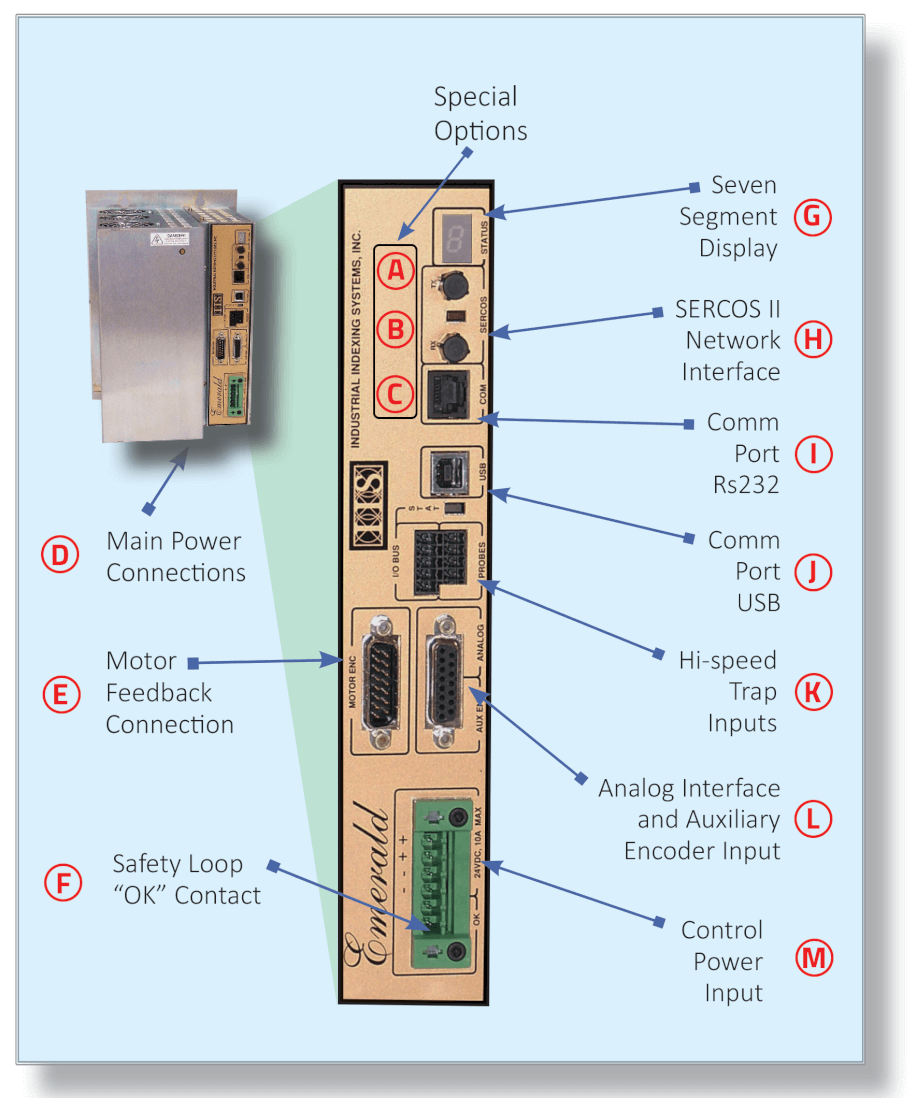

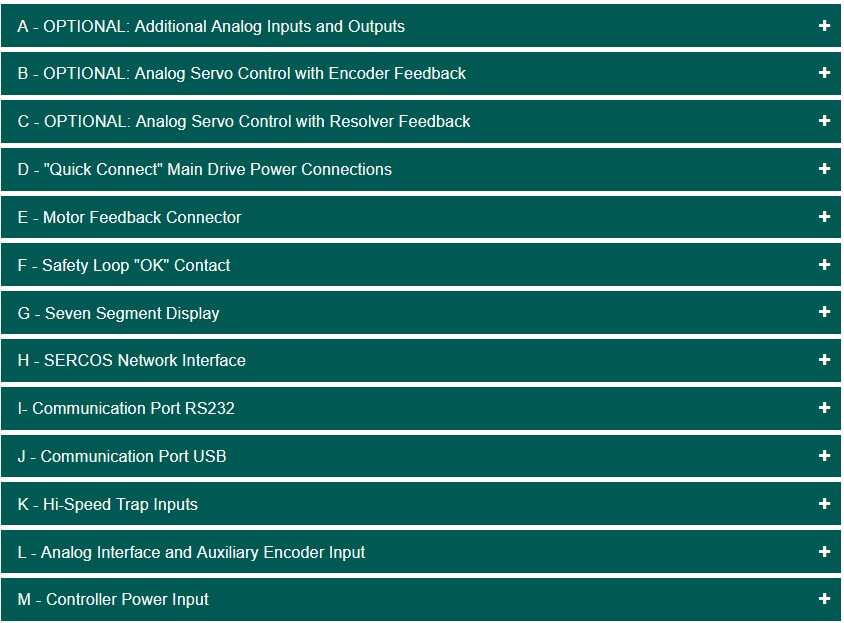

Emerald Drive Features Page

- Go to Emerald Servo Drives page:

https://www.iis-servo.com/products/emerald-servo-drives/ - Scroll to the bottom and click on Emerald Drive Features:

https://www.iis-servo.com/emerald-servo-drive-features/ - From here you will see a labelled diagram for the Emerald Drive Features

- Underneath there is an accordion style listing and as you click on each one there is information/diagrams/drawings explaining each feature.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

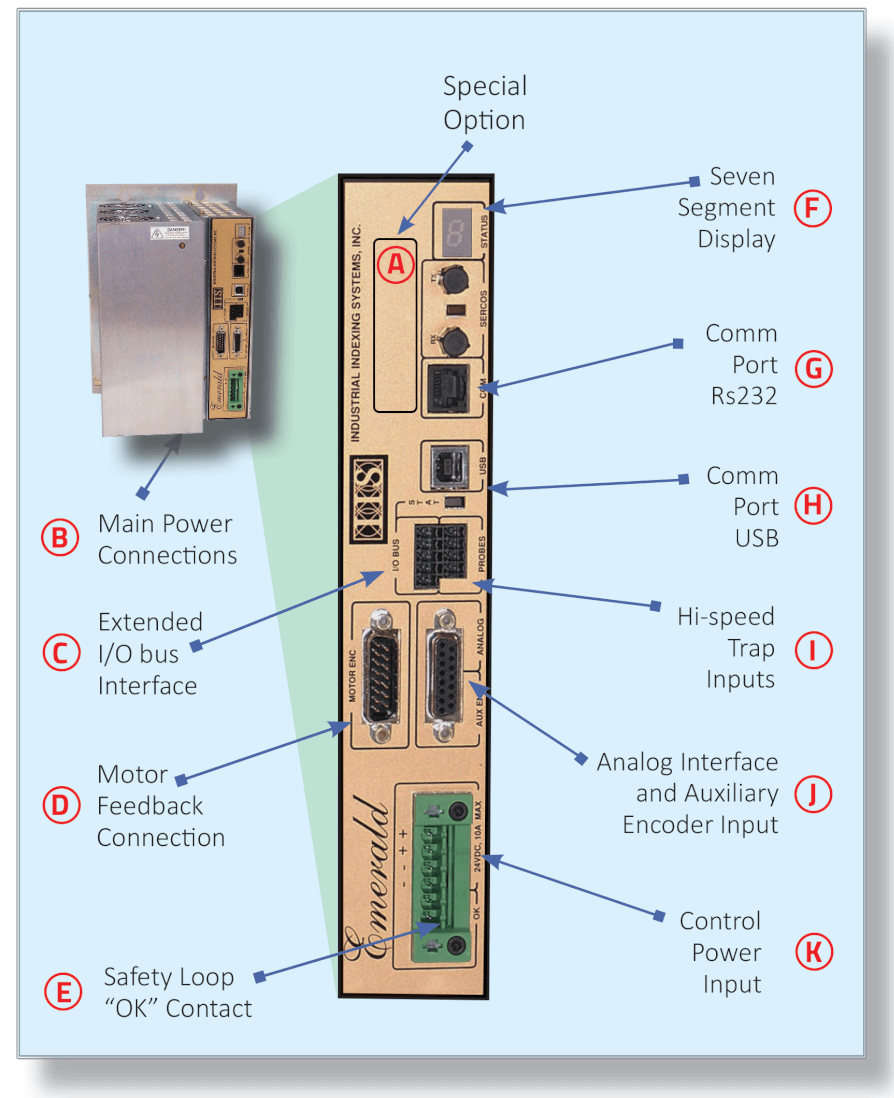

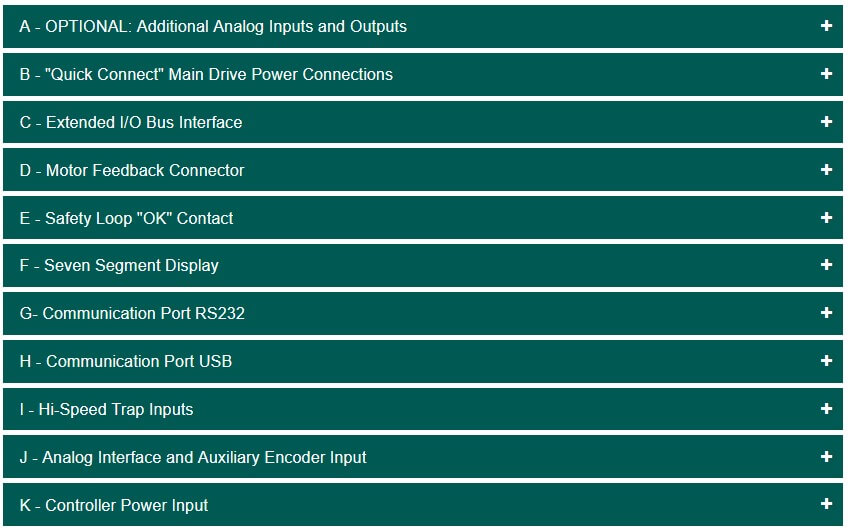

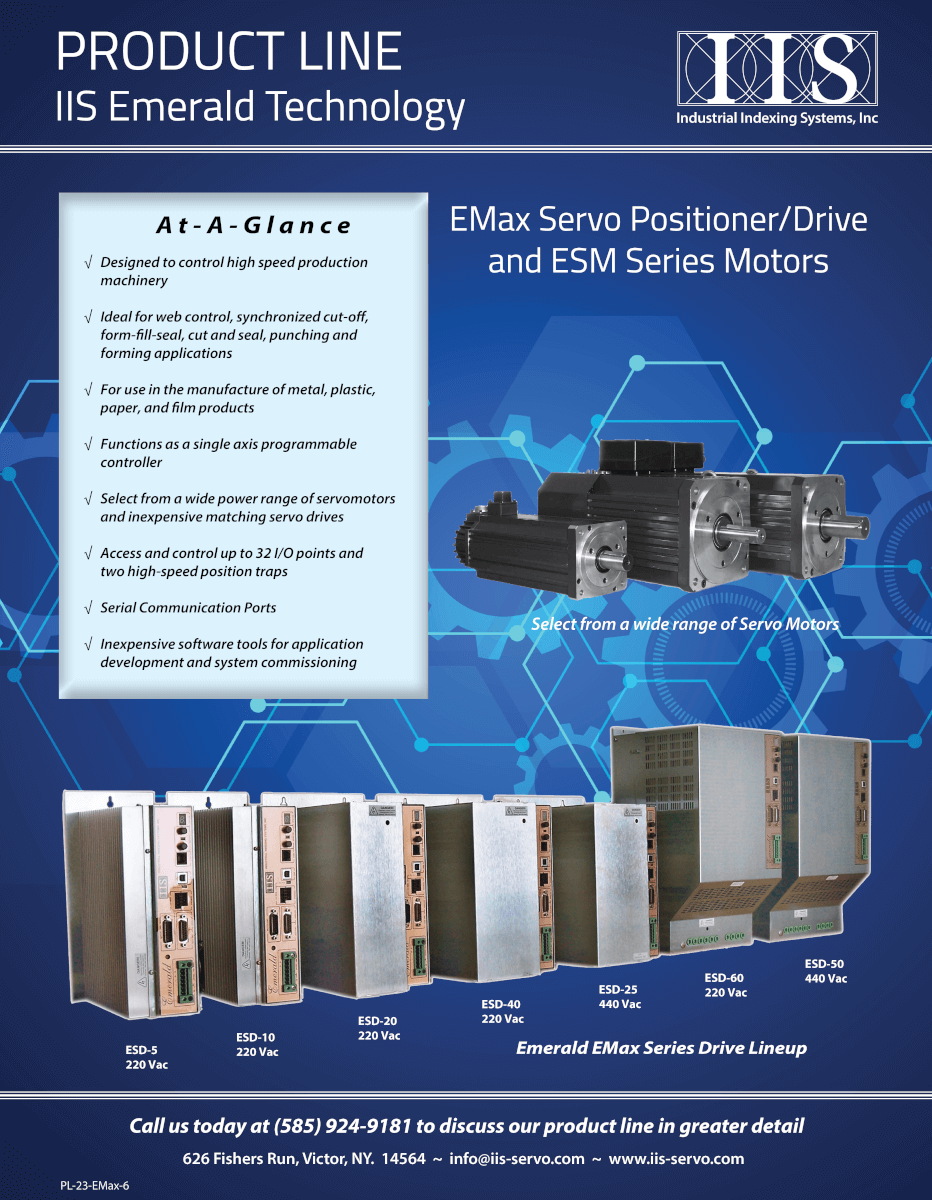

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~EMax Positioner/Drive Features Page

- Go to Emerald Servo Drives page:

https://www.iis-servo.com/products/emax-positioner-drive/ - Scroll to the bottom and click on EMAX Positioner/Drive Features:

https://www.iis-servo.com/emax-positioner-drive-features/ - From here you will see a labelled diagram for the EMax Positioner/Drive Features.

- Underneath there is an accordion style listing and as you click on each one there is information/diagrams/drawings explaining each feature.

- Go to Emerald Servo Drives page:

Marketing Updates

Click on the drop down boxes and select the material/links to download/view

-

Update of the EMax Position/Drive Product Brochure

IIS Web site Link 1: https://www.iis-servo.com/support/product-brochures/

IIS Web Site Link 2: https://www.iis-servo.com/products/emax-positioner-drive/

-

Update of the Emerald Technology Product Brochure

IIS Web site Link 1: https://www.iis-servo.com/support/product-brochures/

IIS Web Site Link 2: https://www.iis-servo.com/products/emerald-automation-controller/

-

Update of the Luminary Series For Motion Control’ product brochure

IIS Web Site link 1: https://www.iis-servo.com/support/product-brochures/

IIS Web Site Link 2: https://www.iis-servo.com/products/luminary-motion-controller/

-

Next Rep Meeting – June 2023

Dates to be determined

Keep an eye out for our invite email 😉

Featured Application

Bioreactors Leverage Precise Speed Control

Bioprocess control stations and benchtop bioreactors use servo motor controls to implement more sophisticated bioreactor control strategies.

Bioprocess Control Stations:

| 1 | Bioprocess control stations are being designed as a universal platform capable of meeting the ever changing needs of all segments of the biotech and pharmaceutical sciences. Suitable for microbial to cell culture, scaling up to scale down and batch to fed-batch processing, new solutions has the right combination of features within an ultra-compact footprint. |

| 2 | Software solutions include the ability to control up to eight units from a single user interface, automatic gas mixing algorithms which simplify control (4-gas, 3-gas), along with O2 and N2 enrichment and a ten-point cascade feature which enables more sophisticated control strategies. |

| 3 | Bioreactor control systems are being loaded with features including easy to use graphical user interfaces (GUI). Systems offer the ability to monitor and control the pH, dissolved oxygen (DO), and temperature with PID control. Implementing a bioreactor motor/ temperature control algorithms enables real-time signals to control the mixer’s servo motor and turn the heater on or off under computer control. |

| 4 | New benchtop scale bioreactors are targeting both mammalian and microbial models. These units can seamlessly transition between autoclavable and single-use bioreactors using a magnetic coupling drive that is fully contained, low maintenance and eliminates any contamination. A servomotor/drive is used to provide low friction magnetic-drive agitation suitable for cell culture & microbial upstream bioprocesses, and is also compatible with autoclavable and single-use vessels. |

Luminary Motion Technology:

| 1 | Medical device manufacturers have been able to use Luminary servo drive technology from Industrial Indexing Systems (IIS) to easily configure these applications using a digital drive interface option. |

| 2 | The digital drive interface option bypasses the normal analog circuit path to allow access to the digital registers which control the operation of the speed control loop. Using the universal RS-485 device bus with Modbus RTU as its connectivity scheme, the digital drive is reachable from a variety of HMI, PLC and PC type controllers. |

Controlling Speed:

| 1 | The drive’s speed control loop consists of a circuit to monitor and control the motor’s torque using a speed command as the input target value. In this control loop process, the speed of the motor shaft is measured on a periodic time-base and compared to the input target value. |

| 2 | Any difference between the two values is applied as a correction to the torque control that is needed to accelerate or decelerate the motor shaft back to the desired speed. The shaft speed stays constant, within a small tolerance, due to the quick reaction time of the correction applied to the torque control loop. |

Coming Soon!

- White Paper – Reciprocating Cut-Off

- NEW product launch